Selected Engineering Projects

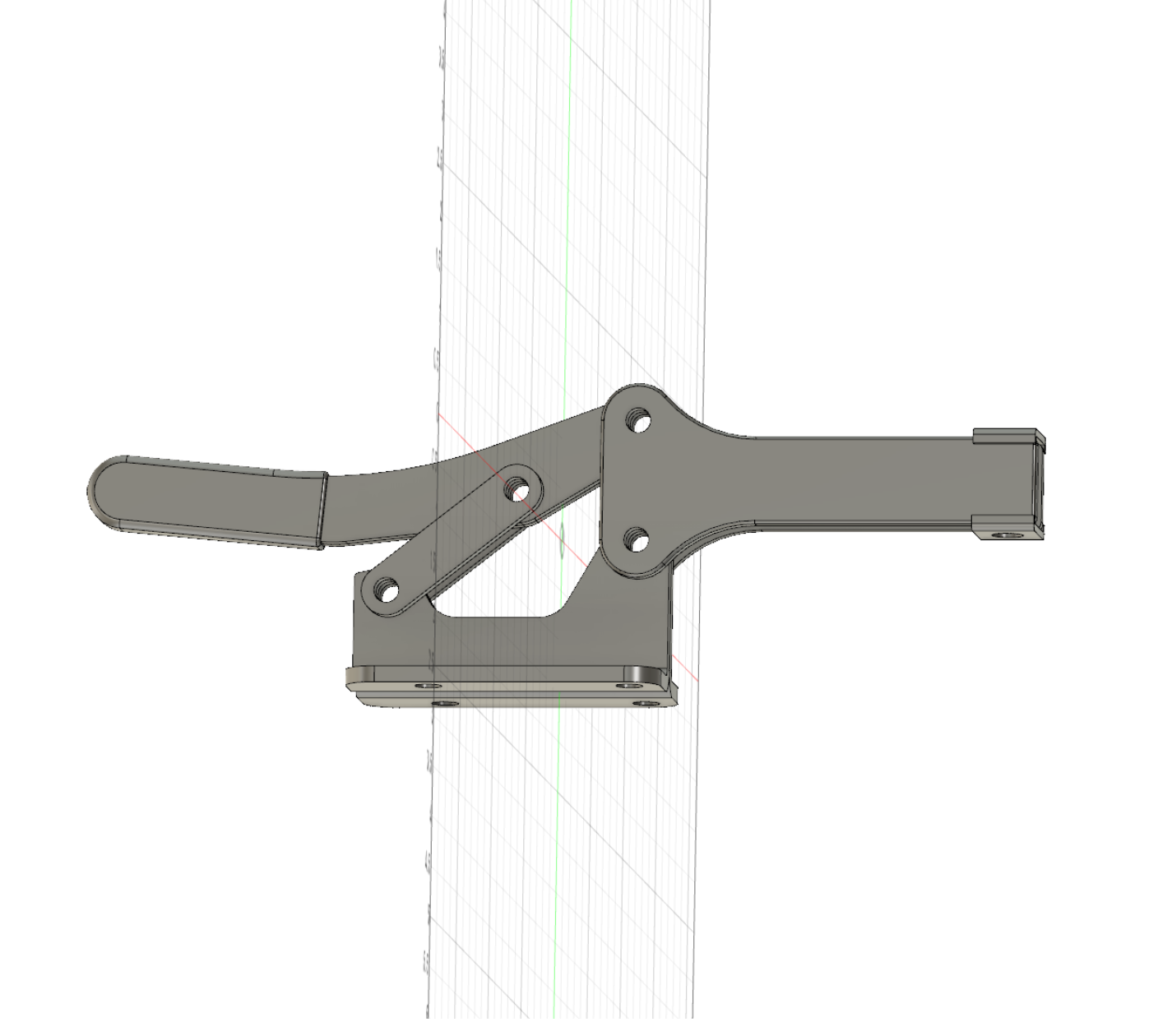

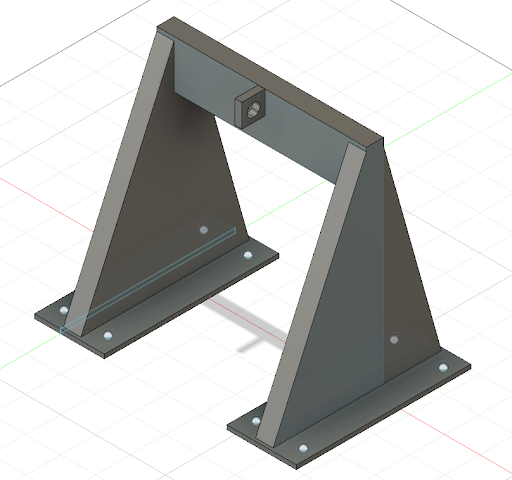

Mechanical Release System for Controlled Hull Flooding

I designed a spring-loaded four-bar toggle clamp to retain and release a sealed hull plug under hydrostatic pressure for controlled flooding in a marine robotic system. The mechanism achieved reliable over-center locking for passive load retention while allowing low-force release at end-of-life. Linkage geometry and mechanical advantage were defined, a preloading anchor bracket was designed to route loads into the base structure, and performance was validated through physical load testing, demonstrating a 2.47× safety factor over the maximum design pressure.

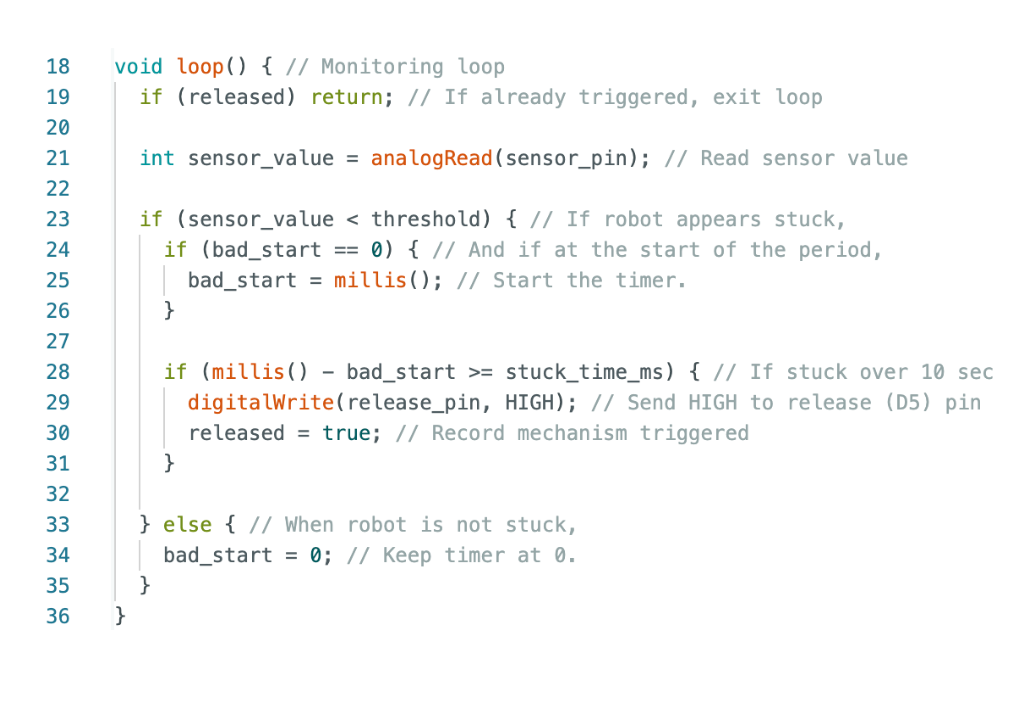

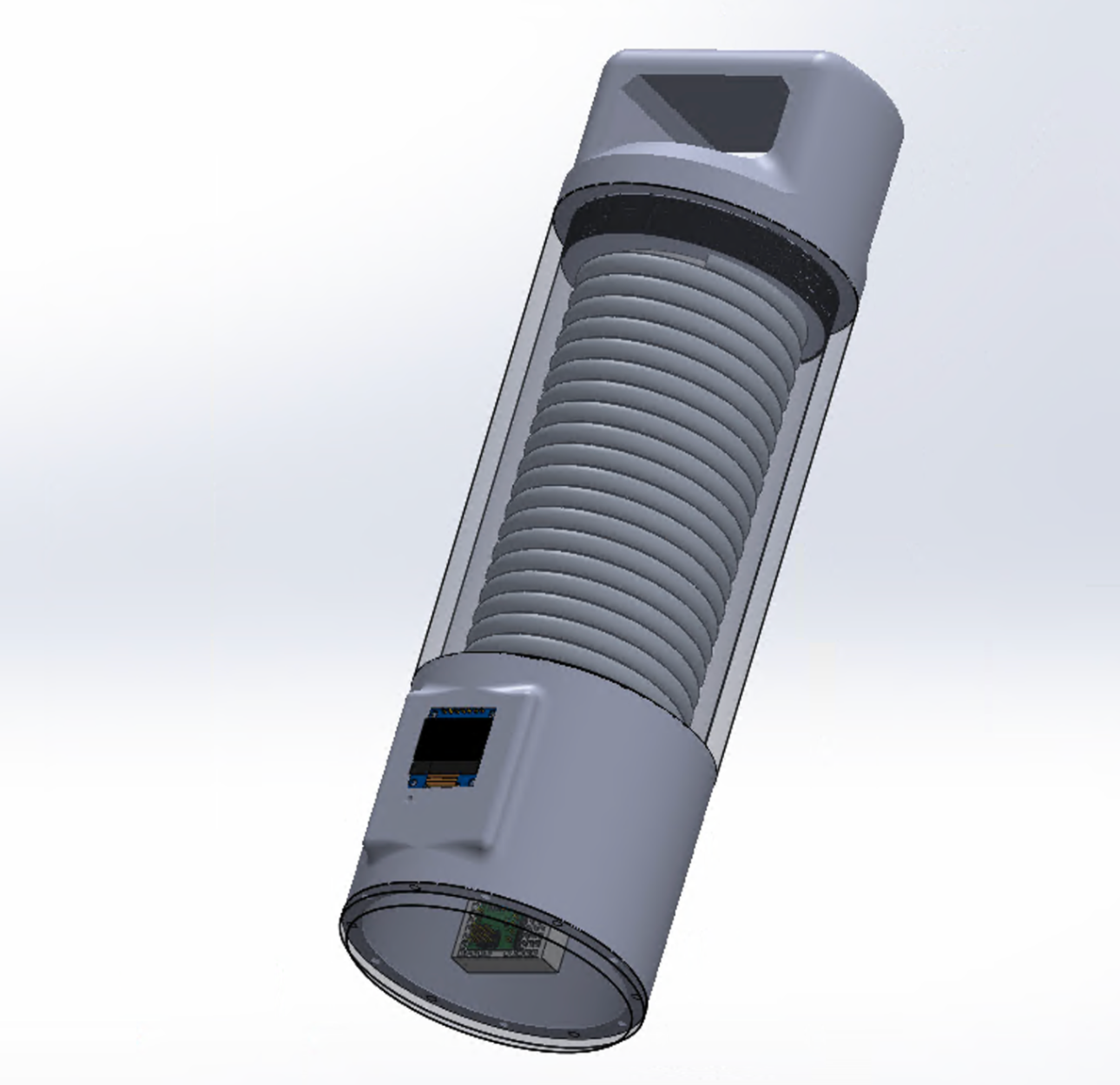

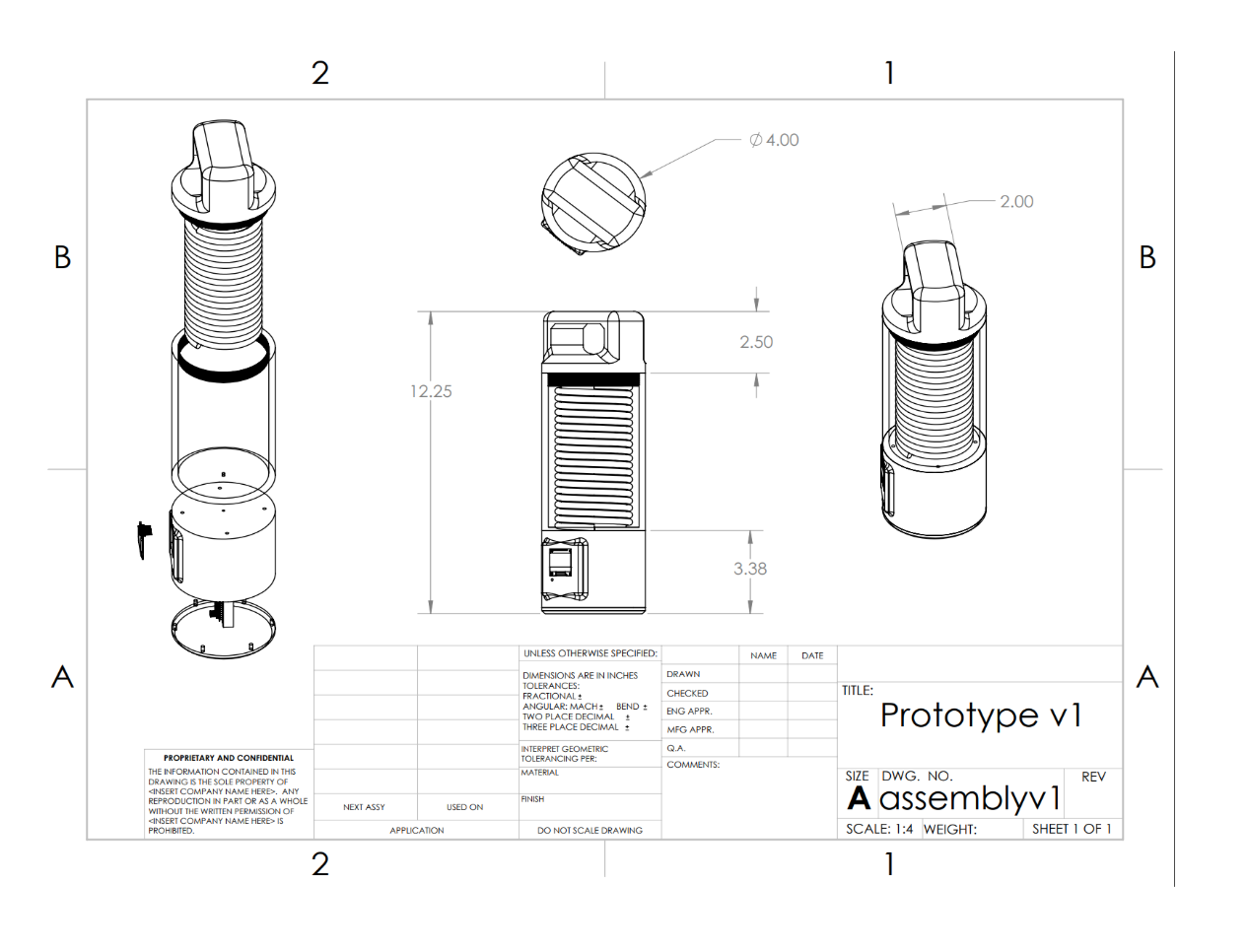

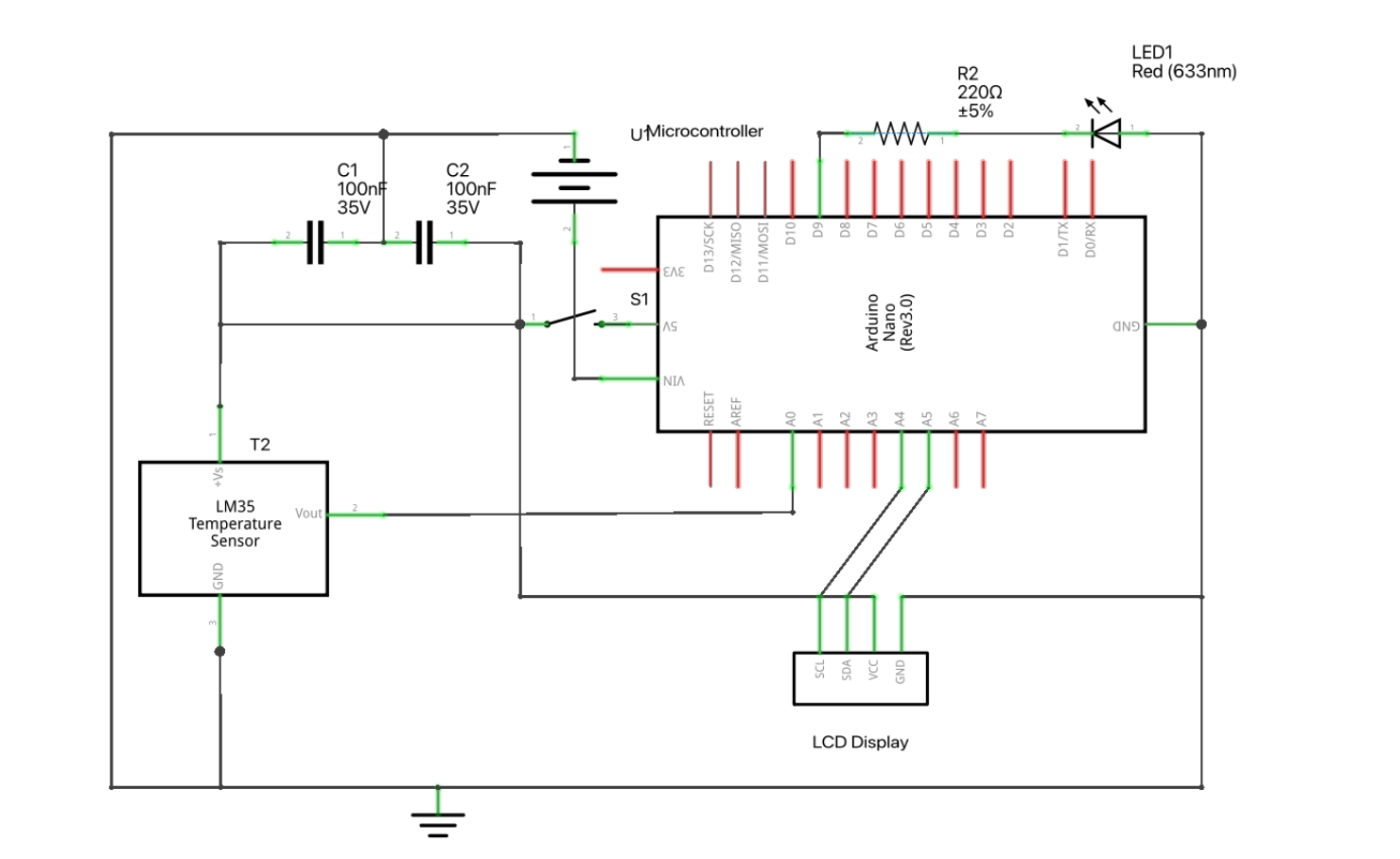

Monitored Portable Thermal Enclosure

This project involved the design of a portable thermal enclosure to maintain temperature-sensitive contents within a defined operating range using controlled heat transfer and internal monitoring. The enclosure combined a conductive aluminum internal cavity with an insulating polymer shell to regulate heat flux and extend phase-change melt time. The system was instrumented to detect and signal out-of-range conditions.

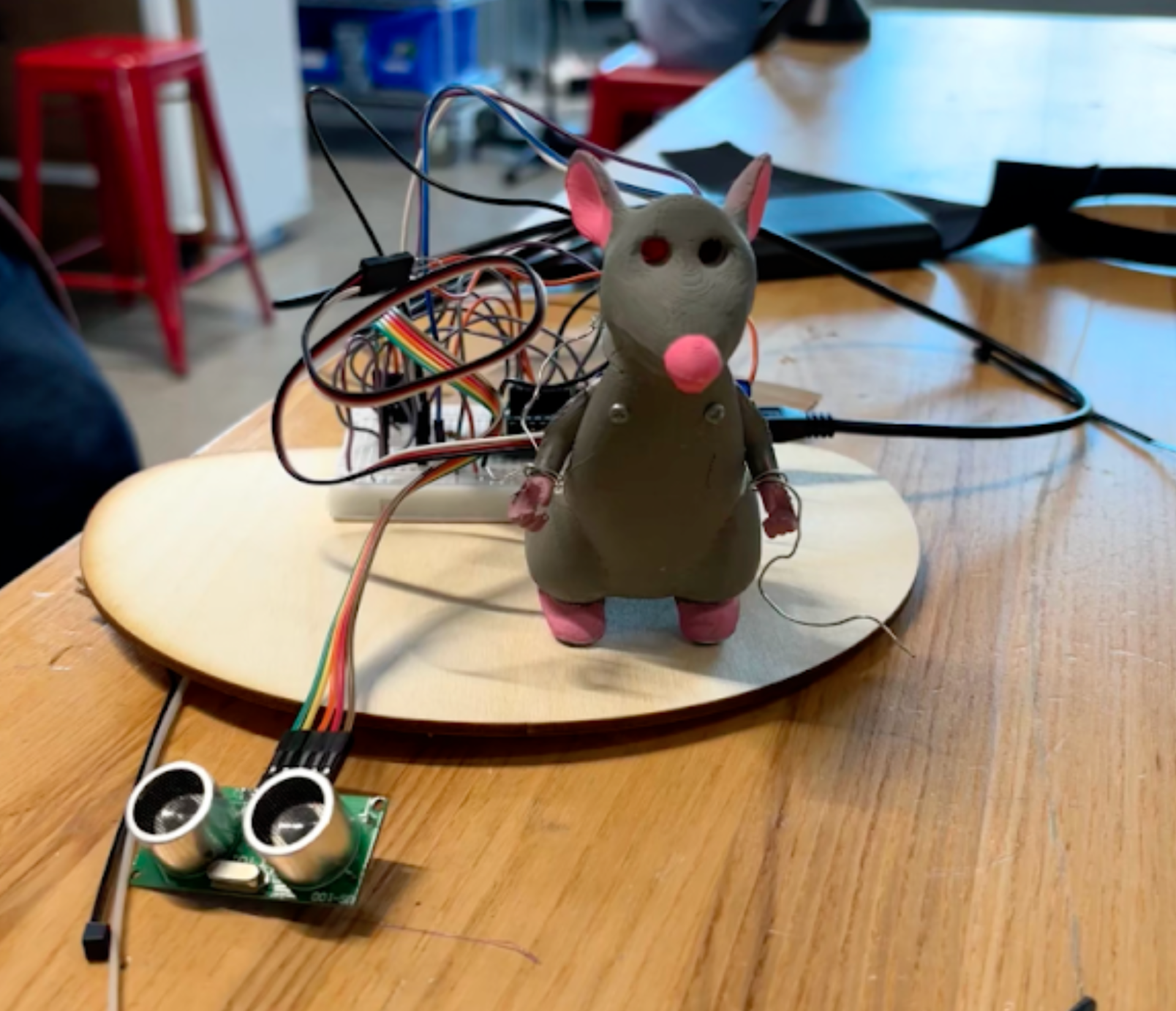

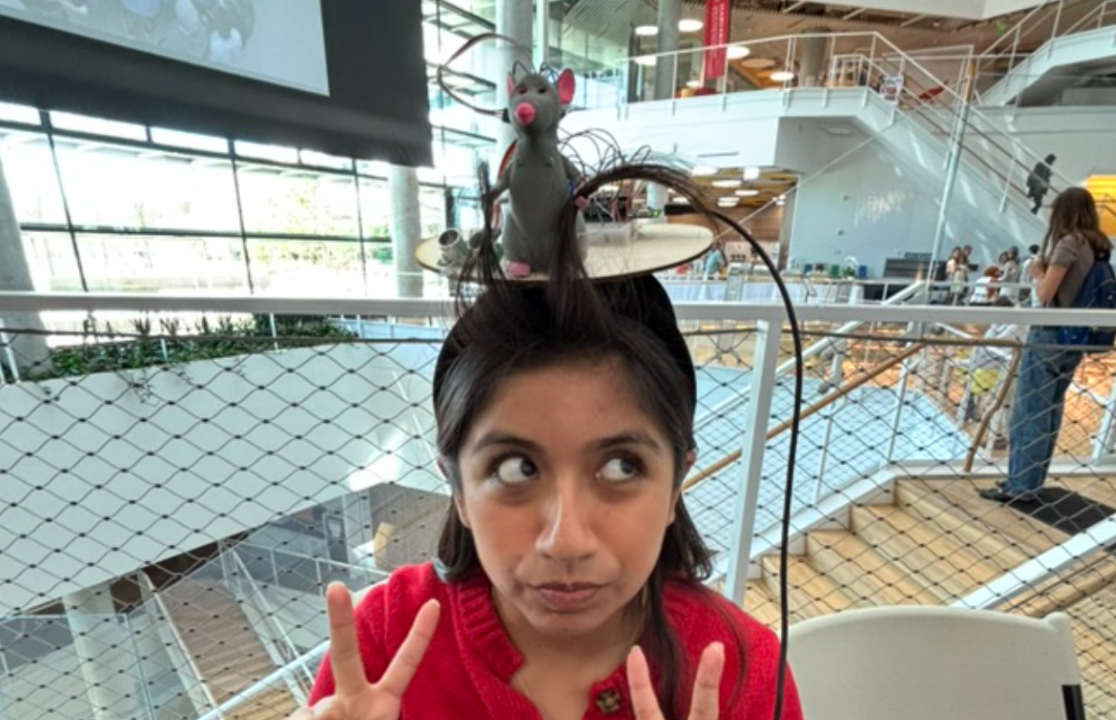

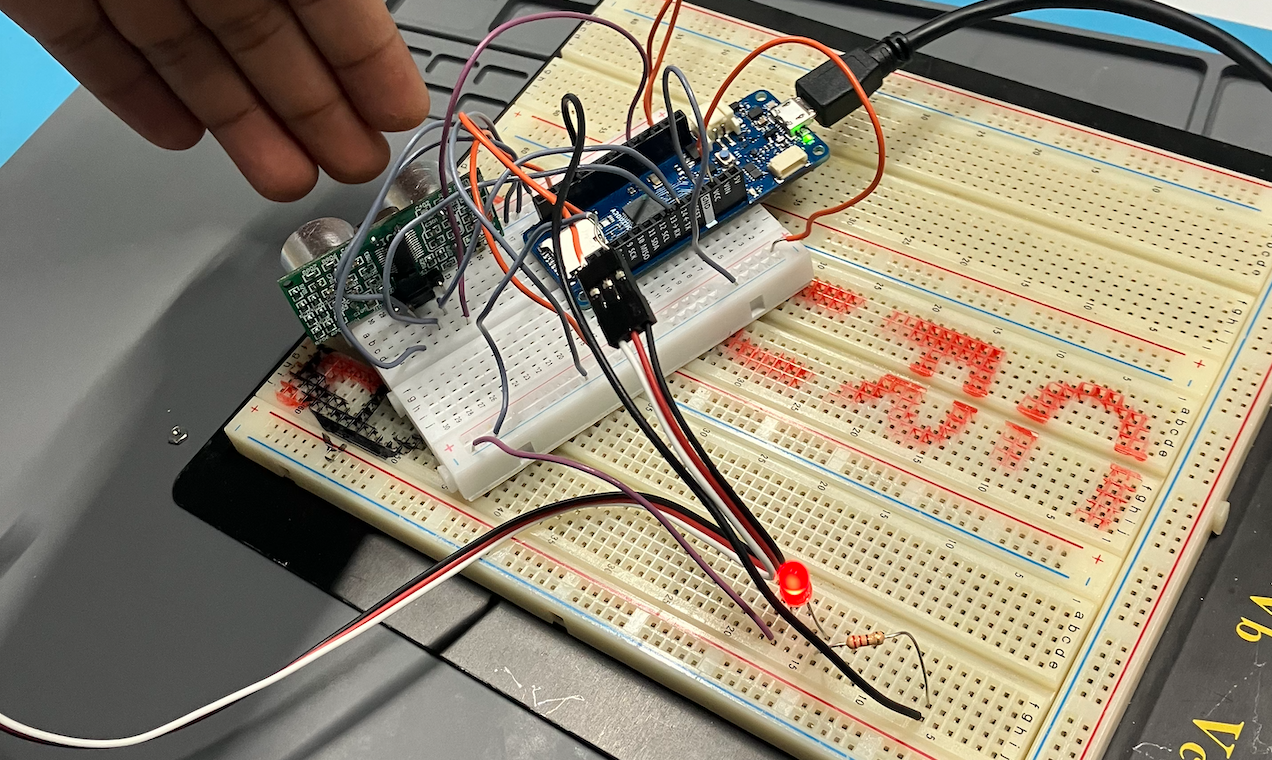

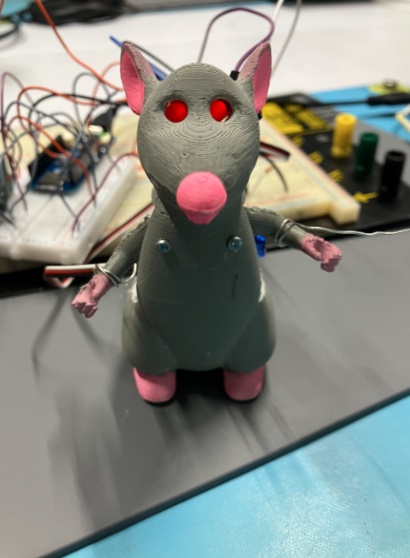

Wearable Electromechanical Actuation System

I built a wearable electromechanical actuation system capable of controlled bidirectional rotational motion. The system integrated a motor-driven mechanical assembly with embedded control and sensing, and was packaged into a head-mounted structure designed for stable operation during motion and user interaction.

Additional Engineering Projects

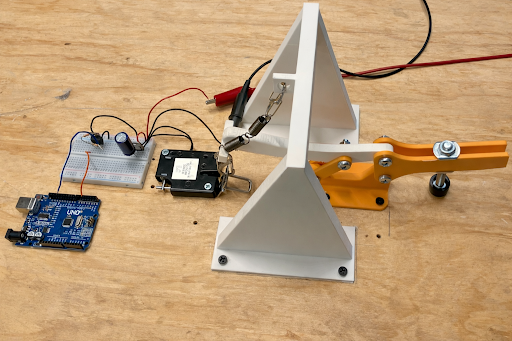

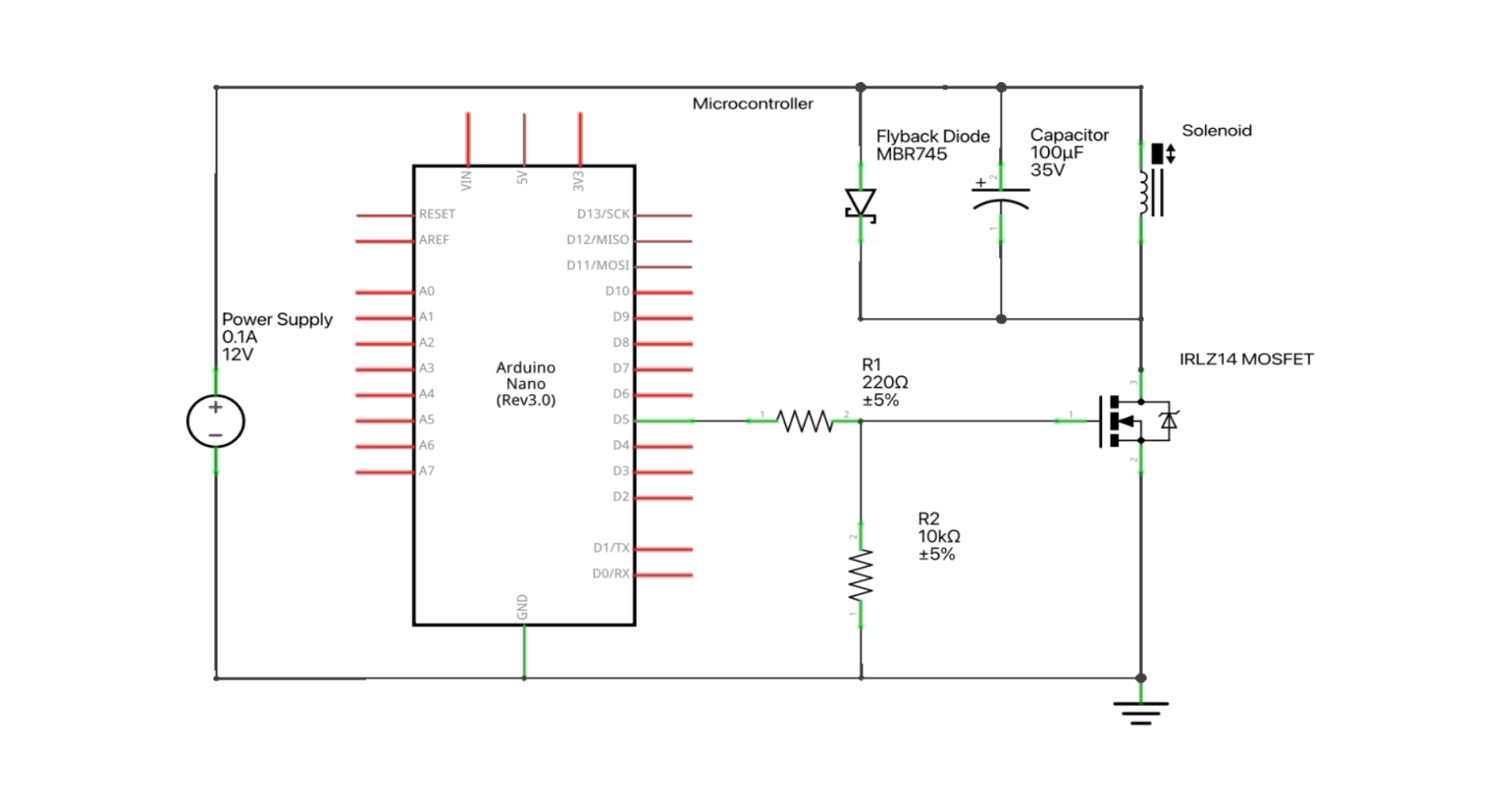

Magnetically Actuated Door Locking Mechanism

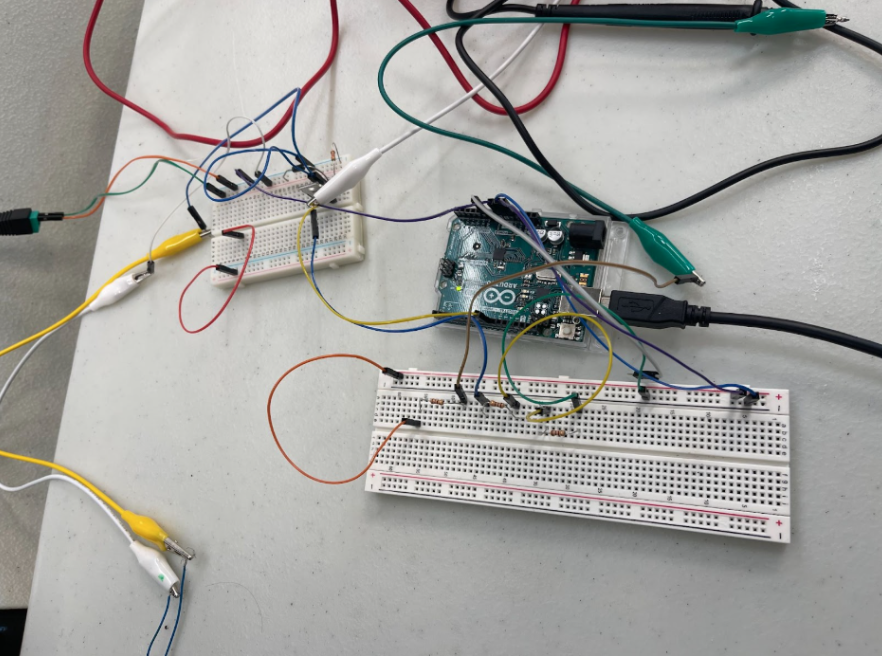

I designed a magnetically actuated door-locking mechanism that uses electromagnetic holding force to secure an enclosure during normal operation. Locking and release behavior were controlled through microcontroller-based power switching, enabling conditional unlocking based on system logic.

Materials: Polymer Microparticle Fabrication and Degradation

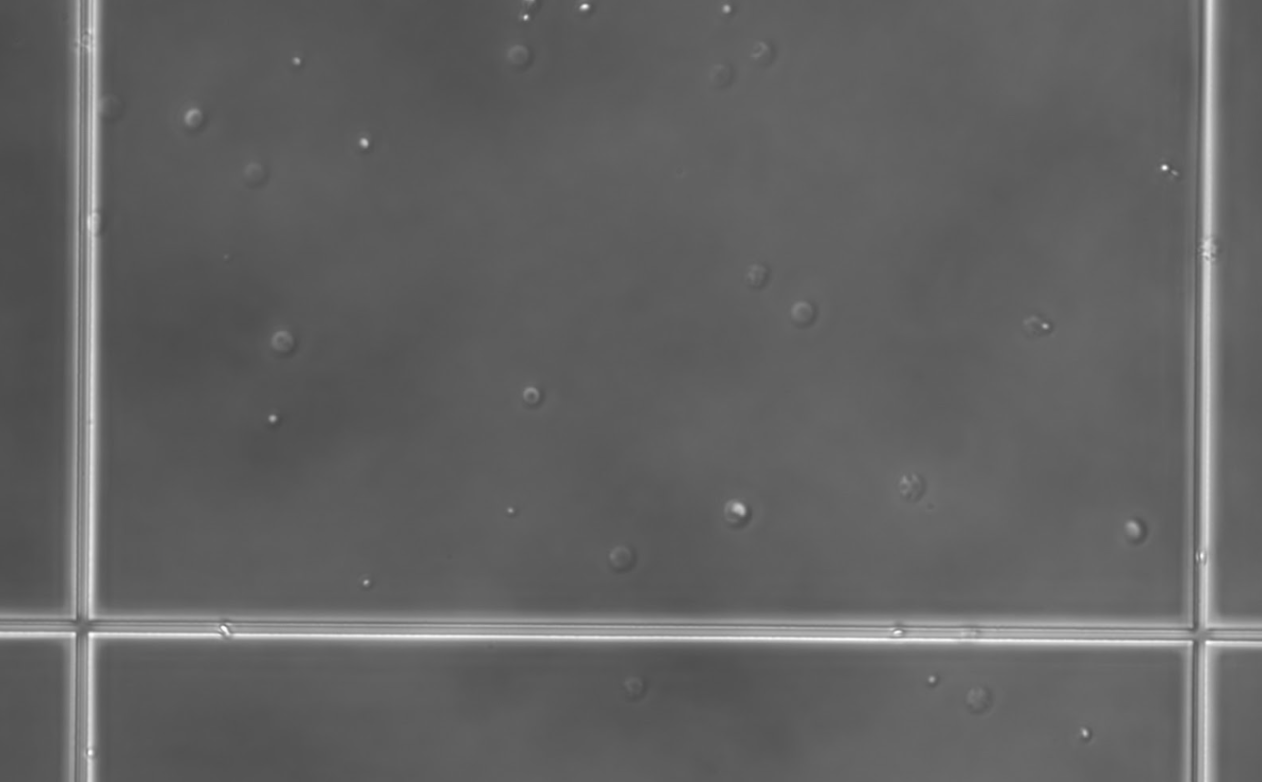

Polymer microparticles with controlled geometry were fabricated using micro-templating techniques for time-dependent degradation studies. Material degradation was characterized through image-based measurement, confirming hydrolytic decay and statistically significant size reduction.

Damped Mechanical Dynamics in Fluids

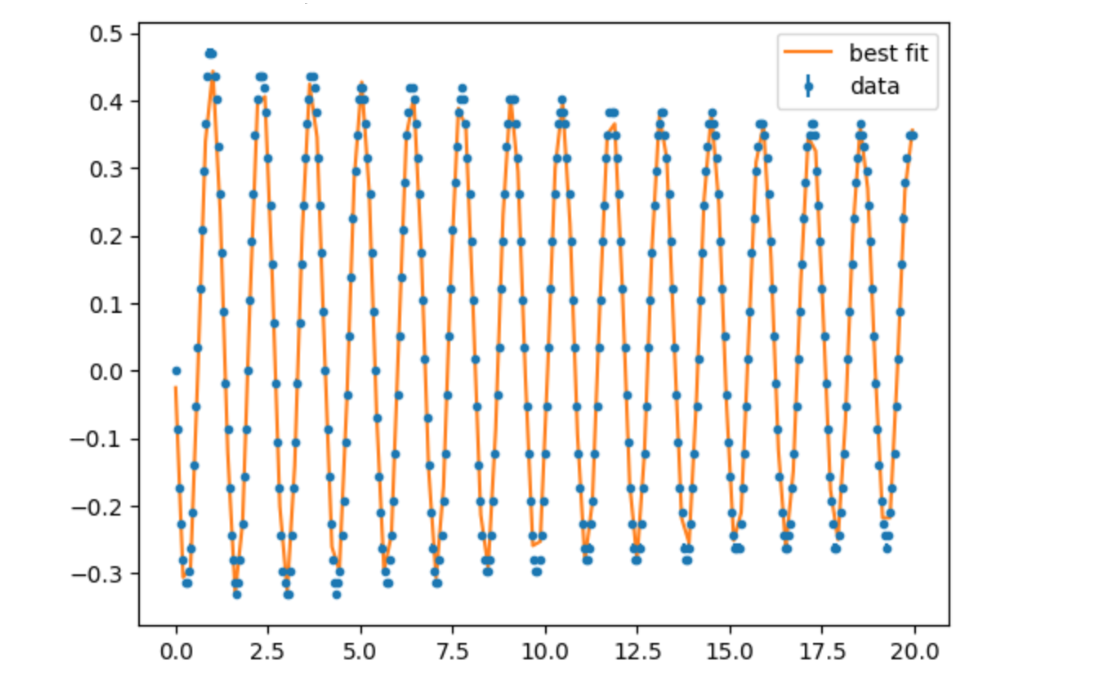

I modeled damped mechanical motion under fluid drag using analytical decay models, fitting parameters to experimental time-series data. The model was applied to compare air and water drag, quantifying the effect of fluid properties on system damping and dynamic response.